Description

The Silver Nanowires have high intrinsic conductivity and high aspect ratio. They can be used to create high optical quality transparent conductive layers.

Catalog Number: NovaWire-Ag-A70

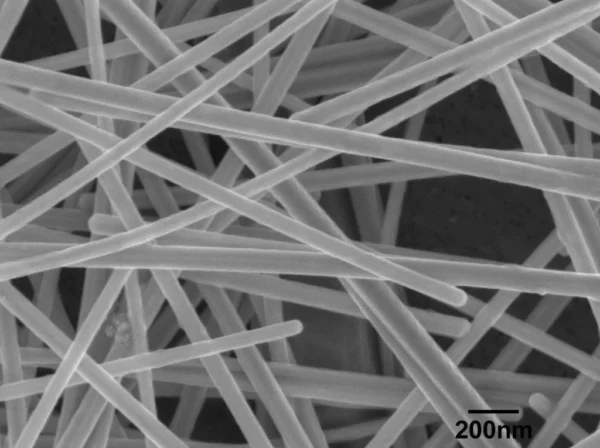

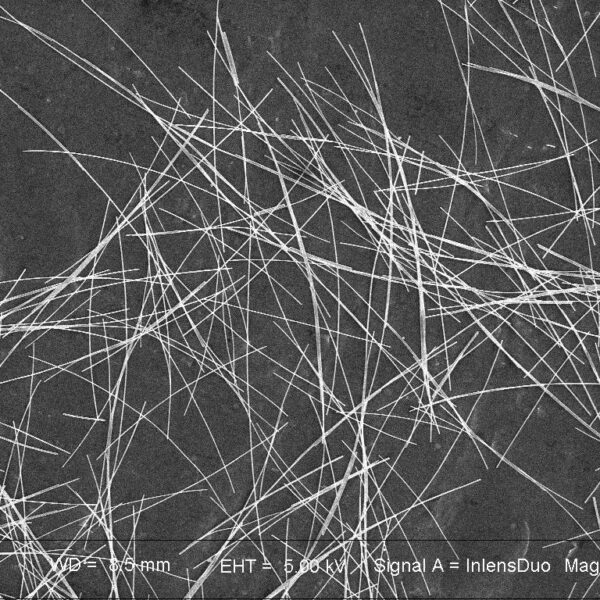

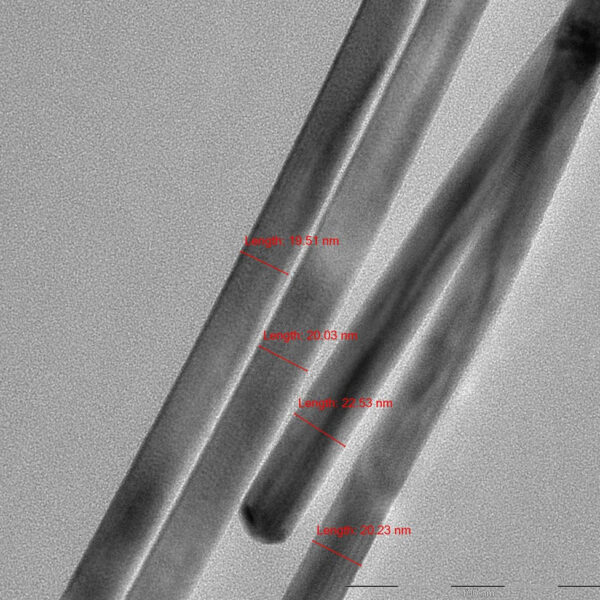

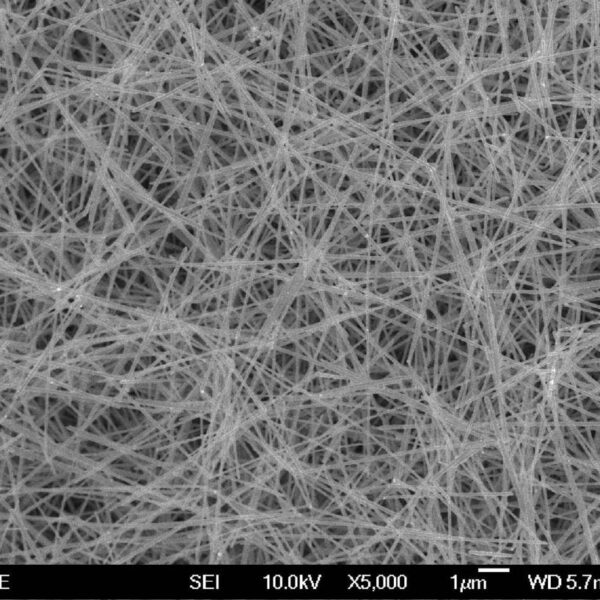

Average Diameter: ~70nm

Average Length: ~50µm

Appearance: gray suspension (dispersed in solvent)

Dispersion solvent: water, ETH, IPA, or customized

Concentration: 5mg/ml, 10mg/ml, 20mg/ml, or customized

APPLICATIONS

Silver nanowires are one-dimensional silver nanomaterials which typically have a diameter in a range of 10-200 nm and a length in a range of 5-200um. They have excellent optical, electrical, thermal, and other properties including high electrical and thermal conductivities, low light extinction in the visible, flexibility, and antibacterial characteristics. Due to their unique properties, silver nanowires have been used in a wide range of applications.

- Transparent Conductive Films: Silver nanowires have been used to create transparent conductive films, replacing traditional materials like indium tin oxide (ITO) in applications where transparency and cost-effectiveness are essential. They are important for applications like touchscreens for smartphones, tablets, and other electronic devices. They are also used as transparent electrodes for solar cells, solar panels, thin film photovoltaics, light-emitting diodes (LEDs), OLED devices, and OLED lighting.

- Flexible Electronics: Due to their flexibility, silver nanowires can be incorporated into flexible and stretchable materials for the development of flexible electronic devices, including flexible displays, wearable electronics, flexible antennas, and bendable sensors.

- Printed Electronics: Inks containing silver nanowires can be formulated to allow precise and controlled deposition of silver nanowires onto different substrates through techniques such as inkjet printing and screen printing. This makes silver nanowires highly valuable in the field of printed electronics, enabling cost-effective and scalable manufacturing of electronic components and devices.

- Flexible Transparent Heaters: Silver nanowires are employed in the fabrication of flexible transparent heaters that can generate heat while providing clear visibility. These heaters are suitable for a variety of applications including automotive defrosting, de-icing and smart windows.

- Antibacterial Applications: Due to silver’s inherent antibacterial properties, silver nanowires are utilized to develop antibacterial coatings for medical devices, surfaces and textiles to inhibit bacteria growth and prevent infections, such as bandages, antimicrobial hospital linens and uniforms. They are also used in air and water purification systems, food packaging, door handles, elevator buttons, and handrails.

- Catalysis: Due to their high surface area and surface reactivity, silver nanowires can serve as catalysts in a variety of chemical reactions and environmental remediation processes. They have been employed in the reduction of organic compounds, organic synthesis reactions, oxidation reactions, and degradation of pollutants, and are of great value in the pharmaceutical and chemical industries.

- Sensors: Due to their high sensitivity, flexibility, and compatibility with various substrates, silver nanowires can be incorporated into various types of sensors for detecting and measuring different substances. They can be used in chemical and gas sensors to detect specific gases or analytes such as ammonia, nitrogen dioxide or carbon monoxide. Their high surface area allows the immobilization of biomolecules, such as enzymes or antibodies, enabling their application in biosensors to detect specific biological substances. The resistance of the silver nanowire-based matrices changes in response to pressure and strain, making them useful in pressure sensors and strain sensors.

In addition, silver nanowires are also applied in the following fields:

- Liquid crystal displays

- e-paper

- Fillers for high performance conductive adhesives

- Surface enhanced spectroscopy (SERS)

- Medical imaging

- EMI shielding films and paints

- Optical limiters

- Waveguides

- Compact logic gates

REFERENCES

- Lee, S., et al. “A fabric-based wearable sensor for continuous monitoring of decubitus ulcer of subjects lying on a bed.” *Scientific Reports*, vol. 13, 2023, Article 5773. https://doi.org/10.1038/s41598-023-33081-7

- Oh, S., et al. “3D Shape-Morphing Display Enabled by Electrothermally Responsive, Stiffness-Tunable Liquid Metal Platform with Stretchable Electroluminescent Device.” *Advanced Functional Materials*, vol. 33, no. 24, 2023, 2214766. https://doi.org/10.1002/adfm.202214766

- Atkinson, J., Abd-Ellah, M., and Goldthorpe, I. A. “Electrochromic Smart Windows with High Near-Infrared Transparency Based on Passivated Silver Nanowire Electrodes.” 2023 IEEE 23rd International Conference on Nanotechnology (NANO). IEEE, 2023. https://doi.org/10.1109/NANO58406.2023.10231172

- Jeong, H.-J., et al. “Highly conductive MXene/Ag nanowire/UV-resin/polycarbonate flexible transparent electrode for capacitive sensors.” *Journal of Inclusion Phenomena and Macrocyclic Chemistry*, 2023. https://doi.org/10.1007/s10847-023-01203-3

- Park, Y., et al. “Large-scale transfer of Ag nanowires from PET to PC film using a roll-to-roll UV lamination process for a capacitive touch sensor.” *RSC Advances*, vol. 13, 2023, pp. 1551-1557. https://doi.org/10.1039/D2RA05600C

- Khandelwal, G., Dahiya, A. S., and Dahiya, R. “Yarn-based UV photodetectors for E-textiles.” 2022 IEEE International Flexible Electronics Technology Conference (IFETC). IEEE, 2022. https://doi.org/10.1109/IFETC53656.2022.9948435

- Muller, J., et al. “Spray-Deposited Anisotropic Assemblies of Plasmonic Nanowires for Direction-Sensitive Strain Measurement.” *ACS Applied Materials & Interfaces*, vol. 14, no. 48, 2022, pp. 54073–54080. https://doi.org/10.1021/acsami.2c14526

- Ojeda, B., et al. “High-throughput tensile testing of silver nanowires.” *Extreme Mechanics Letters*, vol. 57, Nov. 2022, 101896. https://www.sciencedirect.com/science/article/abs/pii/S2352431622001729

- Liu, C., et al. “Fatigue and the electrical resistance of silver nanowire networks.” *Scripta Materialia*, vol. 181, 2020, pp. 97-100. https://doi.org/10.1016/j.scriptamat.2020.02.017

- Heo, Soo Won. “Ultra-Flexible Organic Photovoltaics with Nanograting Patterns Based on CYTOP/Ag Nanowires Substrate.” Nanomaterials, vol. 10, no. 11, Nov. 2020, 2185. PubMed Central, doi:10.3390/nano10112185.

- Heo, S. W. “Ultra-Flexible Organic Photovoltaics with Nanograting Patterns Based on CYTOP/Ag Nanowires Substrate.” *Nanomaterials*, vol. 10, no. 11, 2020, 2185. https://doi.org/10.3390/nano10112185

- Jo, M., et al. “3D Printer-Based Encapsulated Origami Electronics for Extreme System Stretchability and High Areal Coverage.” *ACS Nano*, vol. 13, no. 11, 2019, pp. 12500–12510. https://doi.org/10.1021/acsnano.9b02362

- Xiong, J., et al. “A Deformable and Highly Robust Ethyl Cellulose Transparent Conductor with a Scalable Silver Nanowires Bundle Micromesh.” *Advanced Materials*, vol. 30, no. 36, 2018, 1802803. https://doi.org/10.1002/adma.201802803

- Dong, Jianjin, and Goldthorpe, Irene A. “Exploiting both optical and electrical anisotropy in nanowire electrodes for higher transparency.” *Nanotechnology*, vol. 29, no. 4, 2018, 045705. https://iopscience.iop.org/article/10.1088/1361-6528/aa9ab2/meta

- Lu, C., et al. “Flexible and stretchable nanowire-coated fibers for optoelectronic probing of spinal cord circuits.” *Science Advances*, vol. 3, no. 3, 2017, e1600955. https://doi.org/10.1126/sciadv.1600955

- Lozano, H., et al. “Sizing single nanoscale objects from polarization forces.” *Scientific Reports*, vol. 9, 2019, Article number: 14142. https://doi.org/10.1038/s41598-019-50745-5

SYNONYM

Silver nanowires, silver nanofibers, silver, Ag nanowires, Ag nanofibers, Ag, metallic nanowires, metallic nanofibers, conductive nanowires, conductive nanofibers, conductive inks, conductive pastes, silver nanowire, silver nanofiber, Ag nanowire, Ag nanofiber, metallic nanowire, metallic nanofiber, conductive nanowire, conductive nanofiber, conductive ink, conductive paste

SDS