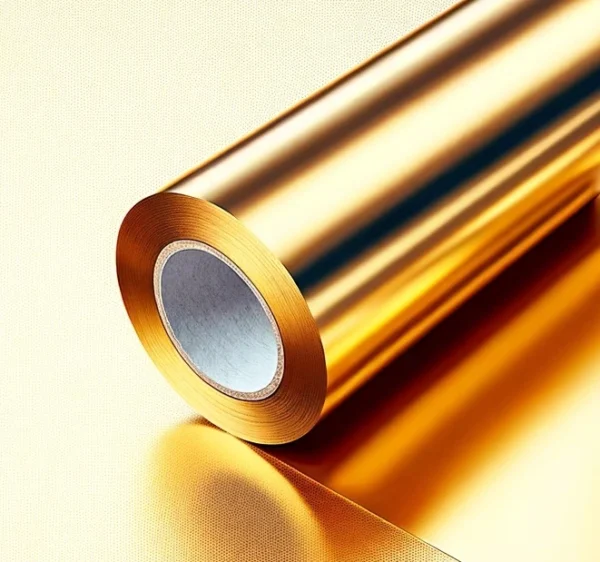

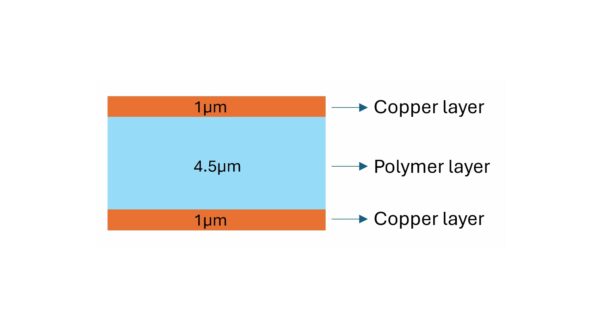

The Composite Copper Current Collector represents a groundbreaking advancement in next-generation battery current collector materials, featuring an innovative sandwich-structured design. At its core is an organic polymer layer, typically polyethylene terephthalate (PET) or polypropylene (PP), flanked by thin copper-plated surfaces on both sides. This structure delivers significant improvements over traditional metal foil collectors. By utilizing ultra-thin copper, it effectively eliminates copper burr formation during electrode cutting, a persistent issue in conventional designs. The polymer substrate offers high elongation and mechanical resilience, reducing the risk of tearing or damage during the coating process. In addition, the design supports higher energy storage capacity and a longer operational lifespan. Fully compatible with existing battery chemistries and manufacturing lines, the composite collector integrates seamlessly into current production workflows. It enables safer, more durable, and higher-performance batteries, positioning it as a pivotal technology for next-generation energy storage across applications including electric vehicles, consumer electronics, and grid-scale systems.

Catalog Number: NovaLIB-Cu-PET

Width: 300mm

Length: 50m

Thickness: ~ 6.5µm

Tensile Strength: MD ~ 240MPa, TD ~200MPa

Elongation Rate: MD ~ 14%, TD ~ 9%

Surface Roughness (Ra): ~ 0.14µm

Sheet Resistance: ~ 18 mΩ/□

Area Density: ~ 25 g/m2

Catalog Number: NovaLIB-Cu-PP

Width: 100mm

Length: 50m

Thickness: ~ 6.5µm

Tensile Strength: MD ~ 160MPa, TD ~180MPa

Elongation Rate: MD ~ 6%, TD ~ 11%

Surface Roughness (Ra): ~ 0.15µm

Sheet Resistance: ~ 19 mΩ/□

Area Density: ~ 22 g/m2

ADVANTAGES

The Composite Copper Current Collectors have the following advantages over traditional current collectors:

- Superior Safety: Significantly reduces the risk of short circuits by effectively eliminating copper burr formation.

- Increased Energy Density: Delivers a ~7% improvement in overall energy density, driven by a ~60% reduction in current collector weight.

- Extended Cycle Life: Enhances battery durability and lifespan through improved mechanical flexibility and structural resilience.

- Lower Manufacturing Cost: Reduces copper consumption, enabling up to a ~70% reduction in production costs at scale.

APPLICATIONS

The Composite Copper Current Collectors are set to find extensive applications across the following sectors:

- Serves as the anode current collector in lithium-ion batteries, lithium metal batteries, and lithium sulfur batteries, prioritizing both high energy and safety.

- Suitable for use in liquid rechargeable batteries, semi-solid rechargeable batteries, and solid-state rechargeable batteries.

Industry-scale product.

SYNONYM

Cu current collectors, Cu current collector