Description

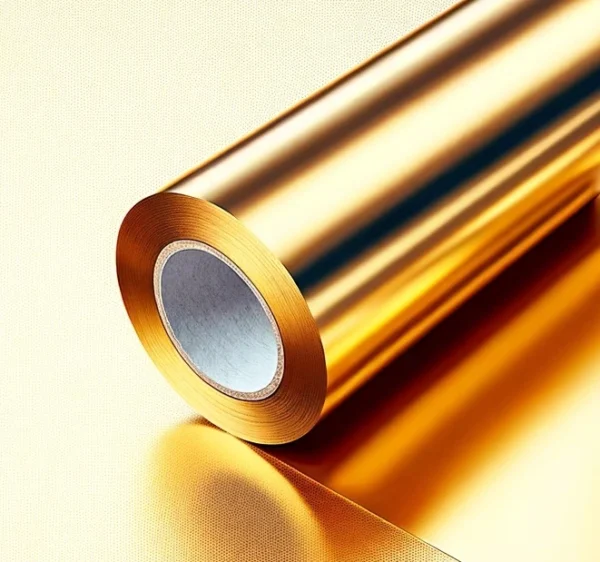

The Composite Copper Current Collector represents a groundbreaking class of next-generation battery collector materials. Its design mirrors that of a “sandwich”, featuring a core layer of organic material flanked by copper-plated surfaces on both the top and bottom. The middle organic layer comprises materials such as Polyethylene Terephthalate (PET), Polypropylene (PP), and Polyimide (PI). This innovative approach to battery current collector offers significant improvements over traditional current collectors, including enhanced safety, reduced costs, increased energy density, extended battery lifespan, and extensive compatibility across various applications.

Catalog Number: NovaLIB-Cu-PET, NovaLIB-Cu-PP, or NovaLIB-Cu-PI

Width: 300mm

Length: 50m

Thickness: ~6µm

Tensile Strength: MD≥200MPa, TD≥180MPa

Elongation Rate: MD≥12%, TD≥8%

Roughness (Ra): < 0.2µm

Area Density: ~25 g/m2

ADVANTAGES

The Composite Copper Current Collectors have the following advantages over traditional current collectors:

- ~60% reduction in weight

- Enhanced safety due to small burrs

- ~70% decrease in production costs at large scale

- ~7% increase in overall energy density

APPLICATIONS

The Composite Copper Current Collectors are set to find extensive applications across the following sectors:

- Serves as the anode current collector in lithium-ion batteries, lithium metal batteries, and lithium sulfur batteries, prioritizing both high energy and safety.

- Suitable for use in liquid rechargeable batteries, semi-solid rechargeable batteries, and solid-state rechargeable batteries.

Industry-scale product, available in various lengths and widths.

SYNONYM

Cu current collectors, Cu current collector